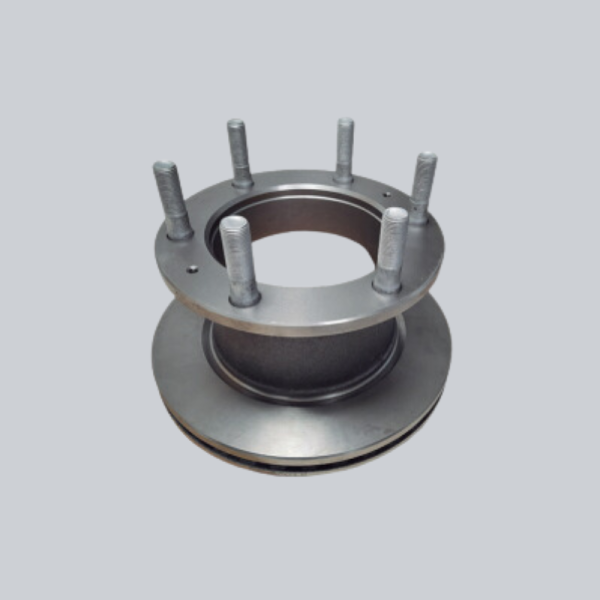

Brake discs

Range of Brake Discs for Brake and Braking Systems

In this specialized category you will find a wide selection of brake discs specifically designed for the maintenance and repair of heavy-duty and commercial vehicles. These components are fundamental parts within the active safety system, responsible for withstanding the friction generated by the brake pads to effectively stop wheel movement.

Our catalogue is aimed at industry professionals, mechanics and fleet managers seeking reliable spare parts for trucks, buses and trailers. We offer references compatible with various brands and models, ensuring that each vehicle can restore its optimal braking capacity and comply with current road safety regulations.

Durability and thermal resistance are key factors in our range. As replacement parts for high-tonnage vehicles, the listed components are manufactured to withstand high temperatures and intensive wear typical of industrial transport, providing stable performance and extending replacement intervals.

Aspects to consider before choosing the replacement part

- OEM reference: Verify the manufacturer’s original reference number to ensure full compatibility with the vehicle.

- Installation axle: Confirm whether the disc is intended for the front axle, rear axle or trailer axle, as specifications vary.

- Disc type: Distinguish between solid or ventilated discs according to the heat dissipation requirements of the braking system.

- Technical dimensions: Check the outer diameter, thickness and total height of the component to avoid installation issues.

- Brake system: Ensure the replacement part is suitable for the brake caliper system brand (for example, Knorr, Meritor, Wabco, etc.).

Frequently Asked Questions

When should brake discs be replaced on a heavy-duty vehicle?

They must be replaced when the disc thickness reaches the minimum specified by the manufacturer, if deep cracks, warping or significant grooves appear. It is also advisable to inspect them if vibrations are felt in the pedal or steering wheel during braking.

Is it necessary to replace the brake pads when installing new discs?

Yes, it is a standard and highly recommended practice in professional mechanics. Installing new pads with new discs ensures proper bedding of the friction surfaces, preventing uneven wear and guaranteeing maximum braking efficiency from the start.

What is the difference between a ventilated disc and a solid disc?

Ventilated discs feature internal channels that allow air to pass through, facilitating heat dissipation generated by friction, making them ideal for axles with high braking loads. Solid discs are a single solid piece, generally used on axles with lower thermal demand.

How can I confirm that the disc is compatible with my truck or bus?

The most accurate way is to consult the vehicle’s technical data sheet and cross-check the original reference (OEM) with the replacement part reference. You may also filter by vehicle brand, model and year, paying close attention to diameter and thickness measurements.