Brake pads

Spare Parts for Brake and Braking Maintenance: Brake Pads

In this section, we offer a specialized selection of friction components intended for the maintenance of heavy-duty vehicles. Brake pads are critical elements to ensure the active safety of trucks, buses and trailers, providing an effective response to the demands of load and road transport.

This catalogue is aimed at fleet managers, mechanics and professionals seeking reliable spare parts to preserve the integrity of the braking system. Our products are designed to provide thermal resistance and durability, helping to optimize service intervals and reduce vehicle downtime.

Criteria for selecting the appropriate brake pad set

- Brake system: Identify the manufacturer of the installed caliper (Knorr, Wabco, Meritor, etc.), as this determines the geometry of the part.

- Installation axle: Verify whether the replacement part is for the steering axle, drive axle or trailer/semi-trailer axle.

- WVA reference: Use the universal WVA number to confirm the exact dimensions and thickness of the friction material.

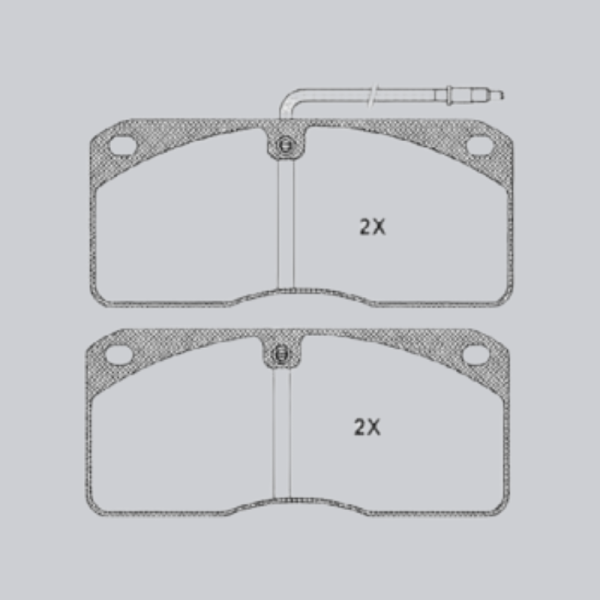

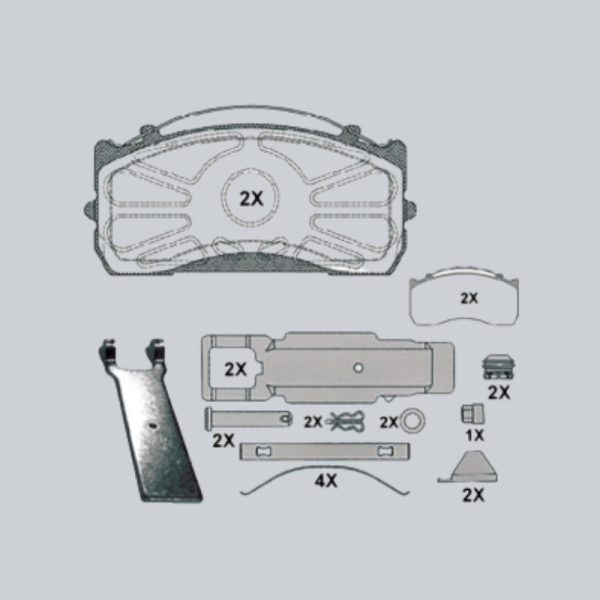

- Installation accessories: Check whether the kit includes retaining springs, shims and wear indicators required for installation.

- Certification: Ensure that the replacement part complies with ECE R90 regulations to guarantee quality and safety on public roads.

Frequently Asked Questions

When should brake pads be replaced on a heavy-duty vehicle?

Replacement is necessary when the friction material is reduced to the minimum thickness specified by the manufacturer (generally 2–3 mm) or when the wear sensor alerts the driver. Service life depends on the type of route, typical load and proper use of the engine brake or retarder.

Is it mandatory to replace brake pads on both sides of the axle?

Yes, the complete axle set (left and right wheel) must always be replaced simultaneously. Replacing only one side would cause braking imbalance, potentially leading the industrial vehicle to lose stability or deviate from its trajectory when pressing the pedal.

What maintenance do new brake pads require?

After installation, it is essential to perform a gentle bedding-in process during the first kilometers. This allows the pad surface to properly seat against the brake disc, maximizing the contact area and preventing issues such as glazing or premature noise.

How do I know which reference my truck uses?

The most reliable way is to consult the vehicle identification number (VIN) in the manufacturer’s parts breakdown or check the reference engraved on the old brake pad. Heavy-duty vehicles may be equipped with different braking systems even within the same model and production year.